-

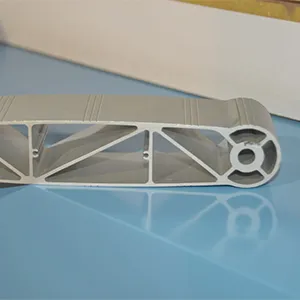

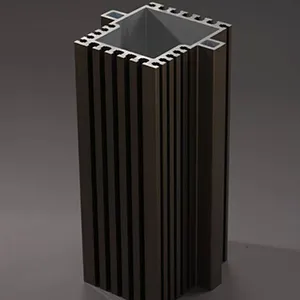

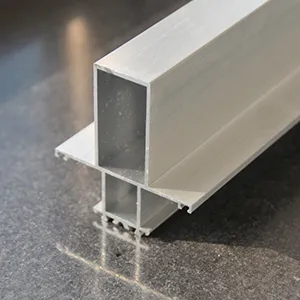

- Standard Aluminum Extrusions For standard aluminum extrusions, extensive production experience and a large mold inventory enable the delivery of durable extruded products at lower cost and with shorter lead time. Learn more

-

- Custom Fabricated Aluminum Components The facility operates over 100 welding machines and 60 machining units, supplying major components to CRRC China, Hyundai Korea, Dawonsys rail manufacturers, and automotive OEMs such as Tesla, BMW, and Chery. Learn more

Zhongpeng has established an experienced design team of over 100 professionals, proficient in CATIA, SolidWorks, UG, ABAQUS, and other design and simulation software. The team conducts model-based weight reduction, structural optimization, and simulation analysis according to client and product requirements. Using CAD/CAM systems for product development, along with advanced finite element simulation software such as Xtrude and QForm, Zhongpeng analyzes extrusion speed, shape, temperature distribution, and material flow to validate mold designs, ensuring the production of durable, long-lasting molds.

Zhongpeng offers fully customized dimensions based on client drawings, with an annual production capacity of 250,000 molds. All molds are produced in-house, supporting maximum dimensions of Φ1250 × 600 mm. The mold workshop is equipped with nearly 100 four-axis wire EDM machines, CNC EDM wire cutting machines, 38 large gantry and vertical machining centers, 10 large mold quenching and pit furnaces, and over 100 advanced milling, sawing, and turning machines, providing a solid foundation for high-precision mold manufacturing.

Zhongpeng specializes in custom production of 6000-series aluminum extrusions, including 6060, 6061, 6063, and 6082 alloys, turning client design concepts into finished products. With a highly skilled technical team, tolerances are strictly maintained within ±0.002 inches, with tighter tolerances available upon request. Each product undergoes rigorous quality inspection to ensure compliance with industry standards. Additional aluminum processing services are offered to meet a wide range of customization needs.

TV components

TV components Aluminum trays

Aluminum trays Table legs

Table legs Beam profiles

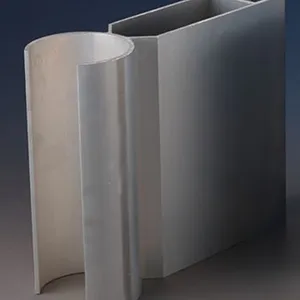

Beam profiles Guide rail profiles

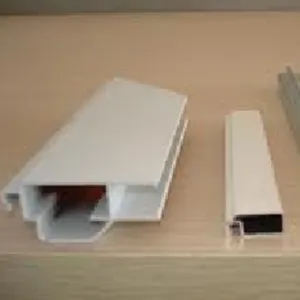

Guide rail profiles Thermal break profiles for doors and windows

Thermal break profiles for doors and windows Door frames

Door frames Curtain wall aluminum profiles

Curtain wall aluminum profiles Aluminum frame materials

Aluminum frame materials

Industries Served

Custom aluminum extrusions provide innovative solutions across various industries to meet diverse application requirements.

Since 1993, Zhongpeng has been a trusted aluminum manufacturer serving a wide range of industries. We deliver durable aluminum extrusions, aluminum coils and sheets, and custom aluminum components to meet the specific requirements of customers across industrial, construction, automotive, rail, electronics and solar sectors.

Can production capacity ensure stable supply for large-volume orders?

What products can be manufactured through the casting process?

What aluminum profiles can be produced through extrusion forming?

The extrusion forming process supports the manufacturing of complex-section aluminum profiles, tubes, and rods used in rail transit, automotive, shipbuilding, and architectural structures. Products can be distributed directly to industrial manufacturers and distributors.

What products can be processed through the rolling process?

The rolling process allows for the production of aluminum sheets and coils suitable for aerospace, automotive, marine, and general manufacturing applications.

What operations are included in aluminum deep processing?

Deep processing covers bending, cutting, welding, and surface treatment operations. These are applied to components such as vehicle bodies, radiators, curtain wall systems, and door and window assemblies.

What types of standard aluminum extrusions are available?

Available standard extrusions include:

- Hollow beam profiles

- Triangular aluminum extrusion profile

- L-shaped profiles

- Aluminum angle profiles

- Channel extrusions

- Flat bar extrusions

- I-beam extrusions

- T-shaped extrusions

- Frame profiles

- Decorative trim profiles