Zhongpeng provides one-stop lightweight solutions integrating structural design, material development, engineering solutions, and manufacturing. In the transportation sector, the company offers comprehensive services covering vehicle design, product optimization, raw material production, forming, surface treatment, product testing, and performance verification.

Lightweight aluminum structural components for vehicle body, chassis, and battery systems

Aluminum is an efficient and cost-effective material for automotive applications. Substitution of steel in vehicle bodies and chassis achieves a weight reduction of 15 to 25 percent. With a high strength-to-weight ratio, aluminum alloys reach tensile strengths of 300 to 500 MPa after treatment, approaching the performance of high-strength steel while remaining lighter. Aluminum also provides fire resistance, weatherability, and natural corrosion protection through its oxide layer, reducing maintenance requirements.

Services cover the full chain from profile design and die development to finished fabrication, producing custom extrusions suitable for lightweight electric vehicles and high-strength safety requirements of conventional vehicles, ensuring weight reduction, operational efficiency, and structural safety.

Highway transportation – all-aluminum bus frames

Highway transportation – all-aluminum trailer components

Drag Beam

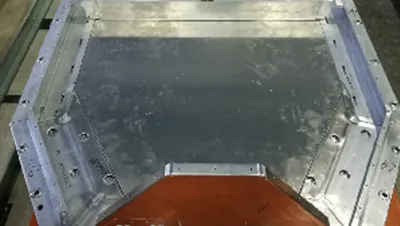

Drag Beam Bottom beam

Bottom beam Front of the bottom beam

Front of the bottom beam Trailer with case

Trailer with case Half-open trailer

Half-open trailer Aluminum trailers

Aluminum trailers

Highway transportation – aluminum tankers

Tesla

Model 3

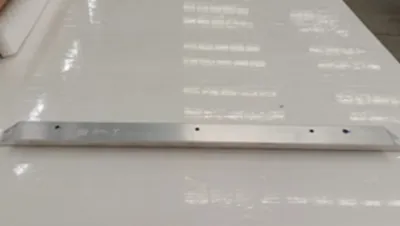

Model 3 Front Anti-Intrusion Beam

Front Anti-Intrusion Beam Front Beam

Front Beam Rear Bumper Beam

Rear Bumper Beam Front Trunk Support

Front Trunk Support

Model Y: I-Beam

BMW

Domestic X5: Left Link Bracket

i3 Electric: Left/Right Link Bracket

G38 5 Series Long Wheelbase: Rear Axle Support Bracket

X3 G08: Right Link Bracket

Jaguar Land Rover

Range Rover Plug-in Hybrid X391: Battery Tray

Jaguar L460 Electric: Battery Tray

Chery

S51EV: Full Vehicle Body Assembly

Huaguan Qantu

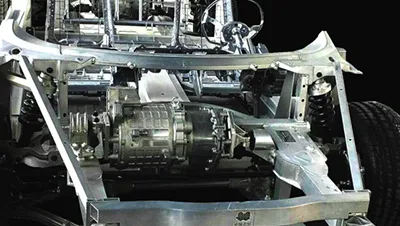

New Energy Sports Car: Full Aluminum Frame Body

Since 1993, Zhongpeng has been a trusted aluminum manufacturer serving a wide range of industries. We deliver durable aluminum extrusions, aluminum coils and sheets, and custom aluminum components to meet the specific requirements of customers across industrial, construction, automotive, rail, electronics and solar sectors.

-

- AutomationModular aluminum profiles and custom structural framing for industrial automation, assembly lines, robotics, and workstations

-

- Rail TransportationHigh-strength aluminum extrusions and profiles for subway, metro, and railway car body structures

-

- 3C ElectronicsPrecision-fabricated aluminum housings, heat sinks, and structural components for electronic, communication, and power systems

-

- SolarAluminum solar panel frames and support systems for photovoltaic racking and mounting