Zhongpeng provides one-stop lightweight solutions integrating structural design, material development, engineering solutions, and manufacturing. In the transportation sector, the company offers comprehensive services covering vehicle design, product optimization, raw material production, forming, surface treatment, product testing, and performance verification.

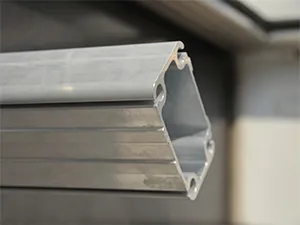

Aluminum extrusions and custom fabricated aluminum components for industrial applications

Aluminum is recognized as an efficient and cost-effective material in industrial use, valued for its light weight, high ductility, and environmental advantages. Its core strengths lie in its excellent strength-to-weight ratio, corrosion resistance, thermal and electrical conductivity, and processing flexibility. These balanced properties make aluminum one of the most versatile materials in modern industry, capable of meeting demands for strength, durability, adaptability, and sustainability.

The anodizing process further enhances aluminum’s advantages. Through electrochemical treatment, a dense oxide layer forms on the surface, improving corrosion and wear resistance, making aluminum ideal for applications such as automated equipment frames and chemical processing structures that require long-term durability.

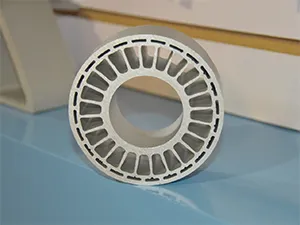

With reliable formability, aluminum extrusions can achieve complex cross-sections through extrusion and be further shaped by bending or machining to meet precise dimensional requirements. Zhongpeng’s engineering team provides comprehensive services, covering extrusion design, production, and final component customization, ensuring that each aluminum solution is precisely tailored to meet the needs of diverse industrial applications.

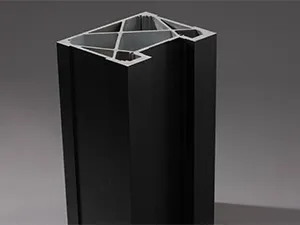

Aluminum profiles for TV components, 6063-T6

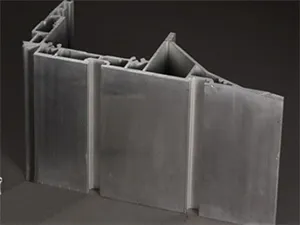

Aluminum profiles for TV components, 6063-T6 Aluminum extrusions for mechanical engineering

Aluminum extrusions for mechanical engineering Aluminum pallets

Aluminum pallets Aluminum ladders

Aluminum ladders Tent frame aluminum extrusions, 6005 and 6061

Tent frame aluminum extrusions, 6005 and 6061 Polished round tubes for table legs

Polished round tubes for table legs Aluminum profile for snow removal equipment, 6005-T6

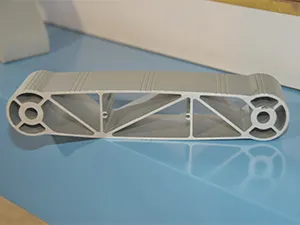

Aluminum profile for snow removal equipment, 6005-T6 Crossbeam aluminum profiles for mining machinery, 6005-T6

Crossbeam aluminum profiles for mining machinery, 6005-T6 Aluminum extrusions for woodworking equipment, 6005-T6

Aluminum extrusions for woodworking equipment, 6005-T6 Robotic guide aluminum rail profiles, 6063A-T5

Robotic guide aluminum rail profiles, 6063A-T5 Large cross-section aluminum extrusions

Large cross-section aluminum extrusions Additional Industrial Applications

Additional Industrial Applications Heat sinks for industrial equipment

Heat sinks for industrial equipment Cable management channels

Cable management channels

Since 1993, Zhongpeng has been a trusted aluminum manufacturer serving a wide range of industries. We deliver durable aluminum extrusions, aluminum coils and sheets, and custom aluminum components to meet the specific requirements of customers across industrial, construction, automotive, rail, electronics and solar sectors.

-

- Building & Construction Aluminum profiles and flat-rolled aluminum products for doors, windows, architectural structures and construction frameworks

-

- Curtain Wall Aluminum profiles for use in curtain wall systems and building façades

-

- Automotive Lightweight aluminum structural components for vehicle body, chassis, and battery systems

-

- AutomationModular aluminum profiles and custom structural framing for industrial automation, assembly lines, robotics, and workstations