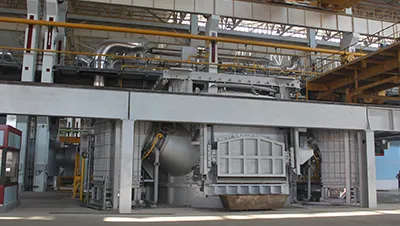

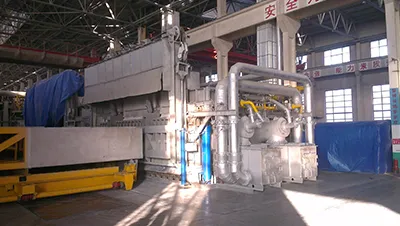

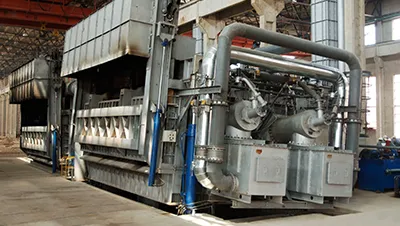

Zhongpeng currently operates 22 advanced casting production lines, including four 63-ton melting furnaces, two 25-ton tilting melting furnaces, six 32-ton square casting furnaces, five 63-ton static furnaces, and five 75-ton homogenization furnaces. Advanced equipment has been introduced from Canada GNA and the United States. The facilities can produce all grades from 1-series to 7-series alloys, with maximum billet dimensions up to Ø582 mm × 7.5 m (length).

The casting process integrates advanced technologies including electromagnetic stirring, online degassing, dual-stage ceramic filtration, oil-gas casting, and online hydrogen monitoring. These measures effectively reduce impurity content, optimize microstructure, ensure smooth ingot surfaces, refine grains, and enhance ingot plasticity, resulting in uniform deformation during subsequent processing.

Advanced homogenization equipment with precise temperature control and well-designed homogenization procedures. Single-stage, two-stage, or multi-stage homogenization schedules are implemented according to the characteristics of different alloys, effectively eliminating intragranular and regional segregation, relieving casting stress, reducing deformation resistance, and improving machining performance. This ensures uniform microstructure, minimizes residual secondary grains, and provides durable cast billets for subsequent production.

The extrusion workshop operates 93 extrusion lines, including 72 extrusion presses below 55 MN, 11 presses at 75 MN, six presses at 90 MN, and four presses at 125 MN. Additionally, two newly introduced 225 MN extrusion presses are set to commence operation, expanding the company’s annual extrusion capacity to 1,000,000 tons.

The extrusion process is supported by equipment including a 16.5 m vertical quenching furnace, a 24 MN hydraulic stretching and straightening machine, a 30 m aluminum profile aging furnace, a single-column hydraulic press, and a roller-type aluminum profile straightening machine.

225 MN Extrusion Press

225 MN Extrusion Press 16.5 m Vertical Quenching Furnace

16.5 m Vertical Quenching Furnace

Behringer bandsaws, 24 MN hydraulic straightening presses, and vertical quenching furnaces

German Behringer Bandsaws

German Behringer Bandsaws 24 MN Hydraulic Straightening Presses

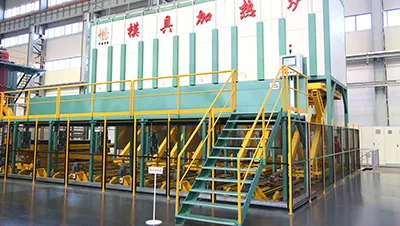

24 MN Hydraulic Straightening Presses Billet Heating Furnace

Billet Heating Furnace Billet Feeder

Billet Feeder  Billet Peeling Machine

Billet Peeling Machine

Zhongpeng currently operates 93 extrusion production lines of various specifications. The extruded profiles fully meet the requirements of large-section and complex-section aluminum alloy profiles, tubes, and rods used in high-speed trains, subways, ships, aerospace, heavy-duty truck bodies, containers, and industrial heat sinks, as well as curtain walls, doors, and window profiles for the construction sector. Production standards are internationally leading, with an annual output of 700,000 tons.

Zhongpeng has invested heavily in advanced equipment imported from abroad, including casting units, homogenization furnaces, hot rolling mills, stretchers, aging furnace units, and quenching furnaces. The facility also includes three-stand, two-stand, and single-stand cold rolling mills, intelligent high-bay storage, bending and straightening equipment, trimming machines, air quenching furnaces, and packing machines. Products serve applications in aerospace, aviation, shipbuilding, chemical industry, transportation, mechanical equipment, and power electronics.

The hot rolling mill has a roll width of 4,500 mm. The air quenching line and composite plate quenching technology feature a total line length of 309 m, capable of producing sheets 0.3–4.0 mm thick and 1,060–2,650 mm wide. It ranks as the world’s second-largest aluminum plate rolling mill.

The SMS cold rolling mill supports a maximum entry thickness of 12 mm, minimum exit thickness of 0.2 mm, with a finished sheet production capacity of 141,000 tons per year.

In the deep processing segment, Zhongpeng employs over 50 engineering technicians and operates more than 200 pieces of equipment. This includes 29 three-axis machining centers, 18 five-axis machines, 85 welding machines, 8 automated welding systems, 1 friction stir welding unit, and 25 bending and rolling machines. These capabilities provide optimized solutions for customers.

FOOKE gantry machining centers are used for welding large railway car body components.

Four-axis machining centers are applied in automotive parts production

Four-axis machining centers are applied in automotive parts production Mubea Systems 5-axis machining centers

Mubea Systems 5-axis machining centers  IGM automated welding robots are used for large component welding and friction stir welding

IGM automated welding robots are used for large component welding and friction stir welding Hartford CNC machining center for automotive component processing

Hartford CNC machining center for automotive component processing Erie press machine (USA) for minor bending of vehicle body components

Erie press machine (USA) for minor bending of vehicle body components COMAC 312CN31-R vertical CNC profile bending machine (Italy)

COMAC 312CN31-R vertical CNC profile bending machine (Italy) Robotic arms

Robotic arms RTI456 IGM automatic welding system for vehicle body assembly (Austria)

RTI456 IGM automatic welding system for vehicle body assembly (Austria)

Zhongpeng operates six anodizing lines, four electrophoretic coating lines, seven vertical powder coating lines, two horizontal powder coating lines, one high-pressure fluorocarbon coating line, five insulation lines, three wood-grain effect aluminum profile lines, two reciprocating polishers, and five mechanical sandblasters.

Anodizing

Powder Coating