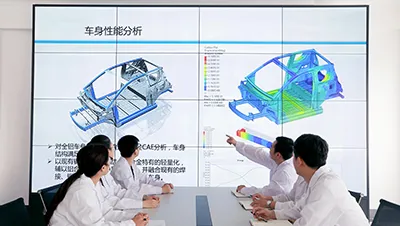

Zhongpeng has established a mature design team of over 100 professionals, proficient in using CATIA, SolidWorks, UG, ABAQUS, and other design and simulation software. The team performs digital modeling for weight reduction, structural optimization, and simulation according to customer and product requirements.

Design work is conducted using CAD/CAM systems, with process analysis performed through advanced international finite element simulation software such as Xtrude and QForm. By simulating extrusion speed, profile geometry, temperature fields, and flow patterns, the team validates mold design feasibility to ensure long-life molds.

Capabilities include design drawings and R&D discussion

Capabilities include battery pack R&D, customization and complete vehicle R&D and customization

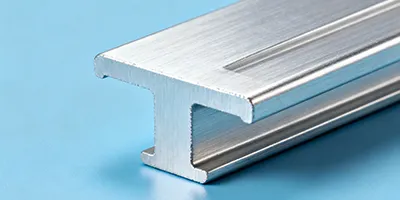

Zhongpeng designs and manufactures molds to meet customer-specific geometric and custom requirements. The company operates advanced mold production equipment with an annual capacity of 250,000 molds, all produced for internal use. The largest molds produced measure Φ1250×600 mm.

The mold workshop is equipped with nearly one hundred wire-cutting machines, including four-axis wire EDM and CNC EDM machines, as well as 38 large gantry and vertical machining centers. Additional equipment includes ten large mold quenching and pit furnaces, and over one hundred milling machines, saws, and lathes, providing strong support for precision mold manufacturing.

225,000-ton extrusion press

225,000-ton extrusion press High-precision machining centers

High-precision machining centers Wire EDM machines

Wire EDM machines CNC EDM machines

CNC EDM machines CNC mold processing centers

CNC mold processing centers