Zhongpeng provides one-stop lightweight solutions integrating structural design, material development, engineering solutions, and manufacturing. In the transportation sector, the company offers comprehensive services covering vehicle design, product optimization, raw material production, forming, surface treatment, product testing, and performance verification.

Modular aluminum profiles and custom structural framing for industrial automation, assembly lines, robotics, and workstations

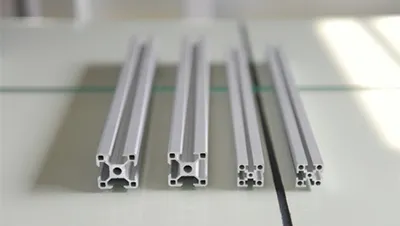

Aluminum extrusions are widely applied in machinery frame structures and various component connections, industrial assembly lines and conveyors, small automated equipment and electromechanical devices, industrial inspection and safety protection systems, electronic and automotive parts assembly lines, as well as medical and food processing equipment and cleaning systems.

Automation aluminum extrusions offer significant advantages. With a density of 2.7 g/cm³, 6061 and 6063 alloys achieve a balance of light weight and high strength after treatment, facilitating equipment handling, installation, and dynamic operation. Standardized grooves eliminate the need for welding, and dedicated connectors allow rapid assembly into frames, shortening production line setup time and simplifying maintenance or modifications. Aluminum profiles can be extruded to custom cross-sections, precisely cut and drilled, suitable for robotic arm mounts, conveyor line frameworks, and other applications. Surfaces are easily anodized or coated, providing resistance to oil and aging, suitable for humid and dusty workshop environments, and maintaining a clean appearance.

Aluminum Frame Profiles (Automation Aluminum Extrusions, Automation Aluminum Profiles)

Alloy: 6063-T6, 6060-T6

Applications: assembly lines, workstations, tool storage

Mold library available for existing profiles

Aluminum Frame Profiles (Automation Aluminum Extrusions, Automation Aluminum Profiles)

Many conveyor line frames are manufactured from aluminum alloys such as 6063-T5, offering high rigidity with low weight. This ensures sufficient support strength without adding excessive mass, enabling flexible equipment layout and handling. Aluminum alloys are easily machined into various shapes and specifications to meet diverse assembly line requirements. Surface treatments, such as silver anodizing, enhance corrosion resistance and extend the service life of frames. Available in various thicknesses (e.g., 1.2–1.4 mm [HZX-147B-1]), extrusions can be customized in packaging, color, and specification for applications including belt lines, assembly lines, frames, and workstations.

Aluminum mobile scaffolds are movable work platforms primarily made from aluminum alloys. They consist of vertical posts, horizontal beams, diagonal braces, scaffold boards, and casters. Vertical and horizontal elements form the main frame, diagonal braces provide stability, scaffold boards serve as work platforms, and casters allow mobility.

Aluminum mobile scaffolds are lightweight, strong, and corrosion-resistant. Compared with traditional steel scaffolds, they are easier to transport and assemble, improving construction efficiency. Their corrosion resistance ensures long service life across varied environments.

Since 1993, Zhongpeng has been a trusted aluminum manufacturer serving a wide range of industries. We deliver durable aluminum extrusions, aluminum coils and sheets, and custom aluminum components to meet the specific requirements of customers across industrial, construction, automotive, rail, electronics and solar sectors.

-

- Rail TransportationHigh-strength aluminum extrusions and profiles for subway, metro, and railway car body structures

-

- 3C ElectronicsPrecision-fabricated aluminum housings, heat sinks, and structural components for electronic, communication, and power systems

-

- SolarAluminum solar panel frames and support systems for photovoltaic racking and mounting

-

- Industrial Aluminum extrusions and custom fabricated aluminum components for industrial applications