Zhongpeng provides one-stop lightweight solutions integrating structural design, material development, engineering solutions, and manufacturing. In the transportation sector, the company offers comprehensive services covering vehicle design, product optimization, raw material production, forming, surface treatment, product testing, and performance verification.

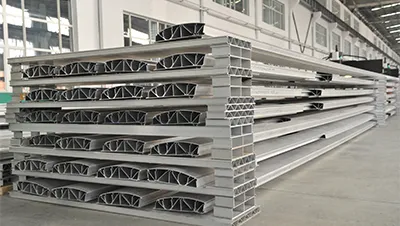

High-strength aluminum extrusions and profiles for subway, metro, and railway car body structures

Aluminum profiles for rail transportation systems offer advantages of low weight, high strength, corrosion resistance, and formability. Zhongpeng supplies aluminum profiles widely used in high-speed rail systems, ventilation systems, automatic door systems, and interior fitting systems. The use of these profiles enhances safety and comfort, reduces energy consumption, improves operational efficiency, and ensures long-term stability of high-speed rail systems.

Aluminum profiles for rail applications demonstrate significant performance advantages. With a density of 2.7 g/cm³ (approximately one-third that of steel), weight reduction of 30–40% can be achieved, minimizing energy consumption and rail wear. Alloys such as 6005A and 6082, after T6 heat treatment, reach tensile strengths of 280–350 MPa with fatigue resistance, ensuring more than 20 years of service life. Their high ductility allows extrusion of long and complex cross-sections. Fire and weather resistance are combined with a natural oxide film that provides inherent corrosion protection; anodizing enhances corrosion resistance four to six times and increases surface hardness. With a near-100% recycling rate and low regeneration energy consumption, these profiles combine sustainability with refined aesthetics. The smooth base material can be processed to achieve diverse colors and finishes. High formability allows the creation of hollow, thin-walled, multi-chamber structures, enabling modular assembly efficiency and adaptability to a wide range of rail transport applications.

Extruded Profiles

Roof profiles

Roof profiles Floor profiles

Floor profiles Profile for roof connection of subway carriage

Profile for roof connection of subway carriage Aluminium profile for subway draft sill

Aluminium profile for subway draft sill Profiles for sidewall and floor of subway carriage

Profiles for sidewall and floor of subway carriage Profile for corbel of subway carriage

Profile for corbel of subway carriage  Conductive aluminum rail profile

Conductive aluminum rail profile

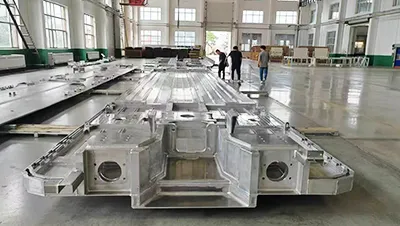

Major Structural Components for Rail Vehicle Bodies

Floor structures

Floor structures Side walls

Side walls End wall panel

End wall panel Roof structures

Roof structures Underframes

Underframes Drag beam

Drag beam Bridge beam

Bridge beam Door frame

Door frame  Door frame

Door frame Head beam of train

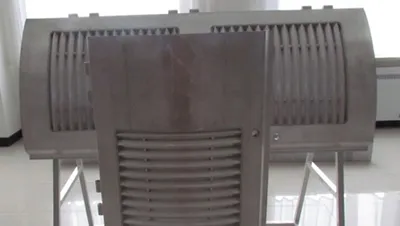

Head beam of train High-speed train components including side skirts, grilles, and handrails

High-speed train components including side skirts, grilles, and handrails Safety handrails

Safety handrails

Passenger Carriages for Railways

High-speed train passenger carriage (ZW-TP-013)

Singapore Project

This project was awarded to Zhongpeng in 2021, covering a total of 186 passenger carriages with an estimated aluminum consumption of 1,200 tons over the project lifecycle. Zhongpeng was responsible for the extrusion and fabrication of aluminum profiles for railway car bodies. All molds were completed in 2021, and material deliveries commenced soon after. The extrusions supplied met stringent international standards for strength, dimensional accuracy, and surface quality, ensuring reliability and consistency throughout production.

Seoul Metro EMU260 Project (South Korea)

Appointed to Zhongpeng in July 2022, this project involved the production of aluminum extrusion and bending for 84 metro carriages, with a total aluminum demand of approximately 800 tons. The project was executed in 14 separate batches to meet the customer’s delivery schedule, concluding successfully in 2024. The supplied profiles were used in the structural sections of the metro car bodies, meeting precision and fatigue resistance requirements for long-term urban rail operation.

Incheon Airport Light Rail Project (South Korea)

Confirmed in July 2022, this project encompassed 54 carriages and required about 400 tons of aluminum extrusions. Zhongpeng provided both railcar body extrusions and custom profile bending, ensuring seamless integration within the lightweight modular structure of the light rail system. All production and delivery phases were completed in 2024, with the materials performing under stringent corrosion and surface durability tests.

Turkey Railcar Project

In June 2023, the client confirmed collaboration with Zhongpeng for the manufacturing of aluminum profiles used in 144 complete train carriages, totaling approximately 1,160 tons of extruded material. The project followed a customized delivery plan aligned with the client’s production schedule. The extrusions supplied featured high-strength 6005A-T6 and 6082-T6 alloys, providing the required rigidity and long-term service life for regional rail applications.

Taoyuan Metro Project (Taiwan)

Officially awarded in December 2022, the Taoyuan Metro project involved 80 carriages with a total aluminum demand of 519 tons, to be executed in two stages. The first phase (2023–2024) covered mold development and initial production, while the second phase (2026–2027) focuses on follow-up deliveries. Zhongpeng’s scope includes aluminum body extrusions and bending components, all manufactured with precision extrusion and homogenization processes to ensure consistent performance and stability.

EMU260 Project (2025)

This project was designated to Zhongpeng in February 2025 for the supply of 84 carriages with a total aluminum requirement of 600 tons. The one-year project includes the full range of railcar body extrusions and select bent components, emphasizing lightweight design, dimensional precision, and corrosion-resistant finishes for long-term operational reliability in metropolitan transit environments.

Since 1993, Zhongpeng has been a trusted aluminum manufacturer serving a wide range of industries. We deliver durable aluminum extrusions, aluminum coils and sheets, and custom aluminum components to meet the specific requirements of customers across industrial, construction, automotive, rail, electronics and solar sectors.

-

- 3C ElectronicsPrecision-fabricated aluminum housings, heat sinks, and structural components for electronic, communication, and power systems

-

- SolarAluminum solar panel frames and support systems for photovoltaic racking and mounting

-

- Industrial Aluminum extrusions and custom fabricated aluminum components for industrial applications

-

- Building & Construction Aluminum profiles and flat-rolled aluminum products for doors, windows, architectural structures and construction frameworks